| ADDITIVE-B | ADDITIVE-C | ADDITIVE-D | |

|---|---|---|---|

| Colour | Light Brownish White | Creamish White | Brownish White |

| Odour | Typical Odour of Starch | Typical Odour of Starch | Typical Odour of Starch |

| Moisture % | 6-7 | 6-7 | 6-7 |

| Starch % | 56 | 83.4 | 42.0 |

| Lignin % | 96.6 | NIL | 13.5 |

| Cellulose % | 22.5 | 4.5 | 32.5 |

| Specialty Chemicals % | 5.2 | 6.0 | 6.0 |

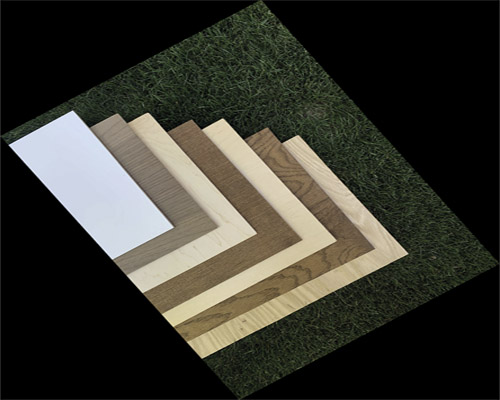

Additive

Extender For Synthetic Resins In Plywod Manufacture

Additive essentially is a starch, modified to improve its properties was developed in 2005 for the plywood sector in India. The specialty chemicals added to improve swelling characteristics of Additive, possess swelling characteristics similar to starch when added to resins. Unlike starch these chemicals do not release water once they swell in the presence of water in the resin. Starch possesses a characteristic known as synarasis, where it tends to release water molecules that are bound with it after swelling.

Specialty chemicals with ability to maintain the required pH & viscosity of the glue mix for over 6 hours are also a part of the composition of Additive.

The plywood industry presently employs Maida as extender in high percentage especially for veneers of Eucalyptus, Rubber etc. with rough surface. This high quantity of starch leads to poor wet strength of the plywood when tested.

Another important factor that influenced the development of Additive was to reduce the starch content in the glue line which made the finished products more susceptible to microbial attack.

The increasing demand for low formaldehyde emission products in the market was also a factor that contributed to the development of Additive.

The free formaldehyde in the resin imparts partial protection against microbes (fungus & mold) and insects (borer & termite). Lack of free formaldehyde coupled with high percentage of starch in the glue line leads to rampant microbial attack of the finished products.

ADDITIVE B:

Additive-B is a unique extender for amino (UF/UMF/MUF) resins. It increases the viscosity of the adhesive mix and thus improves coverage. The specialty chemicals incorporated aid in maintaining the Ph thus reducing the incidence of pre-curing. Viscosity of the resin attained on mixing in the glue mixer, for over 6 hours.

GLUE MIX FORMULATION:

- UF/UMF/MUF Resin - 100 Kgs

- Liquor Ammonia - 1 Ltr

- Additive-B - 4-5 Kgs

- Mix thoroughly for -30-35 mins

- Hardener as required to maintain the pH 6.2 - 6.5

- Flow Time in IS B6 Cup 12 - 14 Secs

NOTE: When UF Resin is used, add MELAMINE after the addition of Additive.

ADDITIVE D:

Additive-D is a mixture of Starch, Ligno-Cellulosic material with specialty chemicals. It is recommended for use with PF / MPF Resin for direct pressing. Additive-D improves the bond strength quality and imparts better finish to the plywood manufactured. Additive-D aids in reducing dry-out when used with modified PF (MPF) resin.

GLUE MIX FORMULATION:

- PF/MPF Resin - 100 Kgs

- Additive-D - 4-5 Kgs

- Mix thoroughly for -30-35 mins

- Flow Time of resin in IS - B4 Cup may be maintained at 30-35 Secs to obtain a flow time of 14 - 16 Secs in IS: B6 Cup for the Glue Mix.

ADDITIVE-C

Additive-C is developed for incorporating in resins used for pre-pressing. Additive-C can be used in both UF /MPF Resins for pre-pressing. It reduces the dry-out in modified PF resin.

In the case of UF/PF Resin, 2-3% Additive-C is added with maida to achieve the required viscosity as it would be uneconomical to use Additive-C alone.

1 kg of Additive-C will replace 2 kgs of Maida.

GLUE MIX FORMULATION:

- UF/UMF/ME/ MPF Resin - 100 Kgs

- Additive-C - 2-3 kgs

- Maida - Quantity as required to obtain desired viscosity

- Mix thoroughly for 30-35 mins

- Flow Time in IS : B6 Cup 45 - 50 Secs

ADDITIVE CON-C

Additive Con-C is the concentrate version of Additive-C developed to reduce transportation costs for far away destinations.

1 kg of Additive CON-C will replace 4 kgs of Maida

GLUE MIX FORMULATION:

- UF/UMF/ME/ MPF Resin : 100 Kgs

- Additive-CON-C - 2-3 kgs

- Maida - Quantity as required to obtain desired viscosity

- Mix thoroughly for 30-35 mins

- Flow Time in IS: B6 Cup 45 - 50 Secs

Properties Of Additive